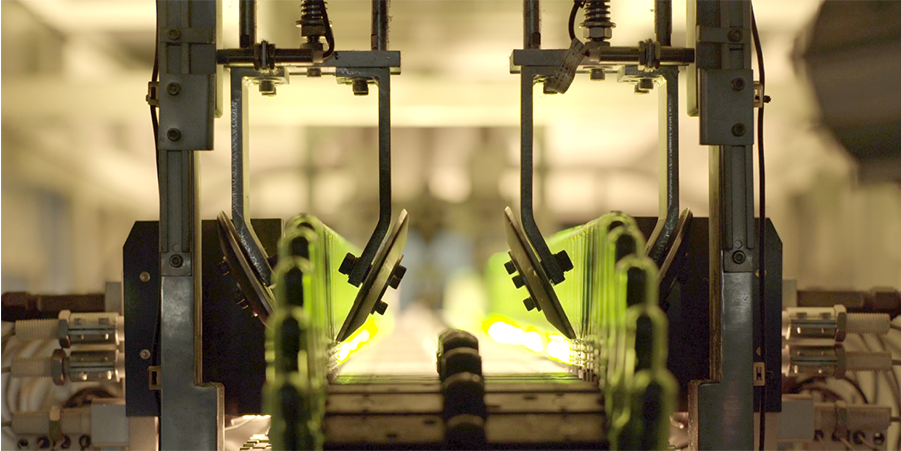

Bottle molding

1. Japan ASB preform injector, crystalizing machine, molding machine

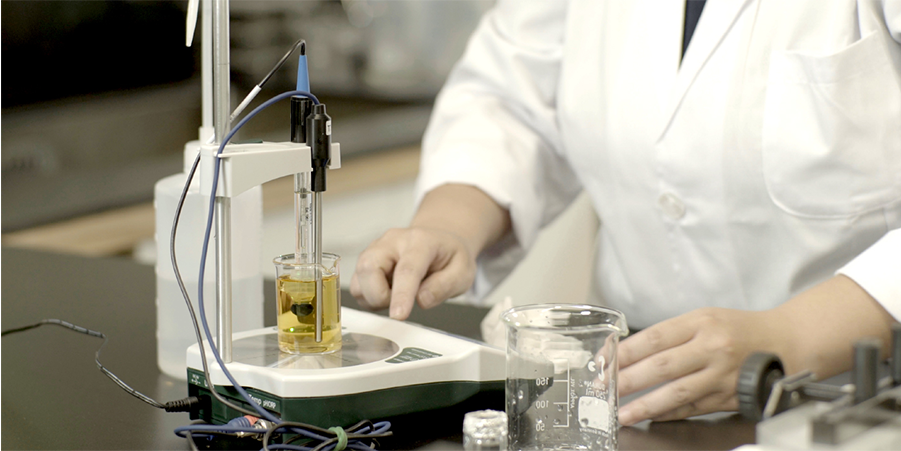

Water quality monitoring and beverage modulation system

1. Apply RO water for conditioning

2. Tea Extracting equipment: Timing control system and lying extraction for product stability

3. Tea liquor clarifying equipment: WESTFALIA tea liquor clarifying machine from Germany

4. Sterilization system: APV UHT tube sterilizing machine

5. Homogenizing system: APV Homogenizer, also works on high viscosity

Filling system

1. Air filtering: Positive system 10000 level filtering equipment

2. Bottle washing: Sterile water is applied for bottle washing

3. Cap washing: Sterile water is applied for cap washing

4. Filling machine set: Three in one filling system with a 500 BPM speed. Both forward and reverse cycle washing is applicable

5. Bottle mouth size: 28mm and 38mm according to demand

Packing and transportation system

1. Lying sterilizing: 40 seconds

2. Cooling system: Hot drenching first, cooling afterward

3. Labeling machine: Double labeling head with 600bpm speed per head. The machine is able to slip label to the mouth

and add an easy-tearing line on bottles

4. Inspector: Equipped with level, capping, side leakage, label, printing, and weight inspection,

we own the most complete inspection system in Taiwan

5. Packing machine: Small packing like 4 and 6, or 8,12,20 and 24. Tray and film are applied

6. Pallet machine: Able to change pallet according to different channels’ need. Pallet film is also applicable

Whole line system

1. Industry 4.0 managing system

2. No preservative added

3. Ability to produce the low-acid product

1. Capacity: Max capacity 50 million per month

2. Domestic to exporting ratio: 70% domestic, 30% exporting

3. Market position: More than 55% hot filling PET bottle market occupation in Taiwan

4. Featuring: Weight-lightening, multiple technologies, the capability of mold development, one station manufacturing, certification,

international sales ability, designing team, food safety control

5. All kinds of bottles from 250ml to 2500ml available

1. Researching over 100 kinds of formulas including tea, juice, pulp drink sports drink and functional drinks

2. Complete market researching and brand building

3. Flavor testing and researching

4. Outer packaging design

5. Channel establishing and regulation study