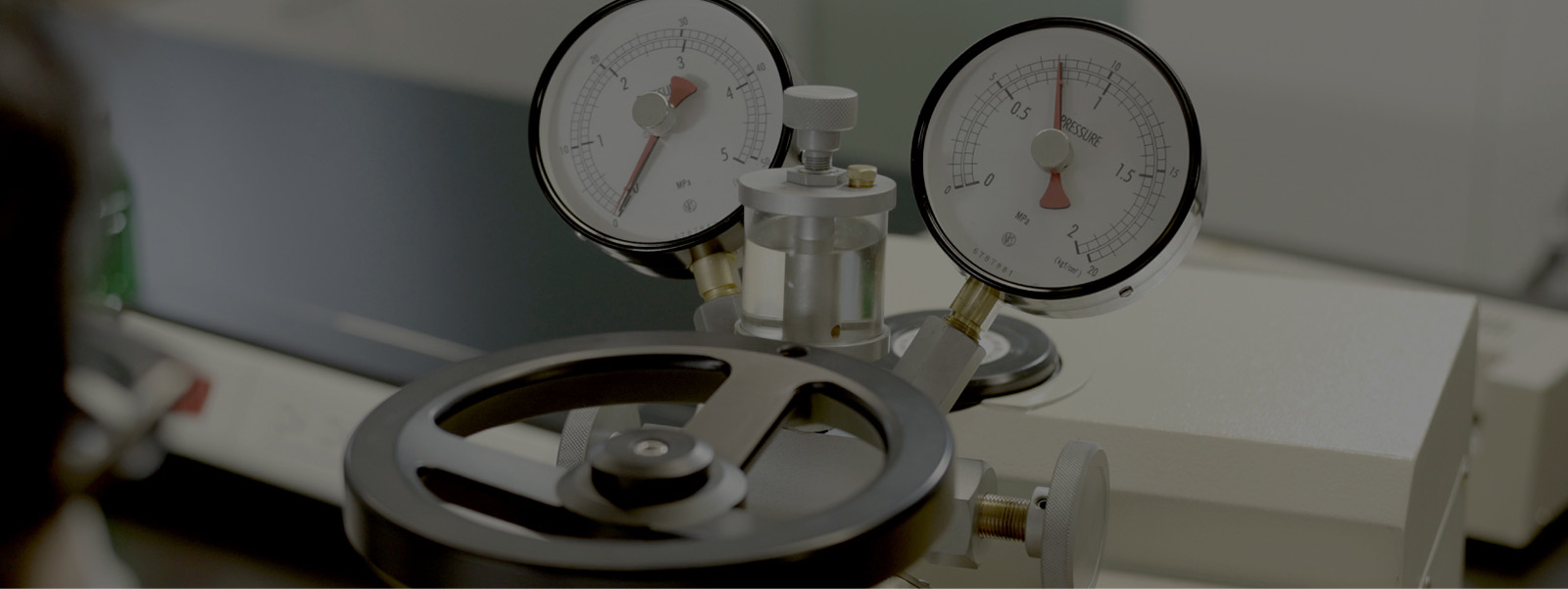

In order to manufacturing the best quality, Target Plastic has many sophisticated and accurate instrument for incoming quality control test. Such as:

Our system is suitable for high speed and numerous capacities of tea extractions, fully controlled by PLC, to make fast and well-distributed extracting tea. Extractor adopted by sectional dumping device, to avoid the tea splashed. Filter device for tea-leaves can be dumped over 90 degrees, easily to remove the tea-leaves without residue.

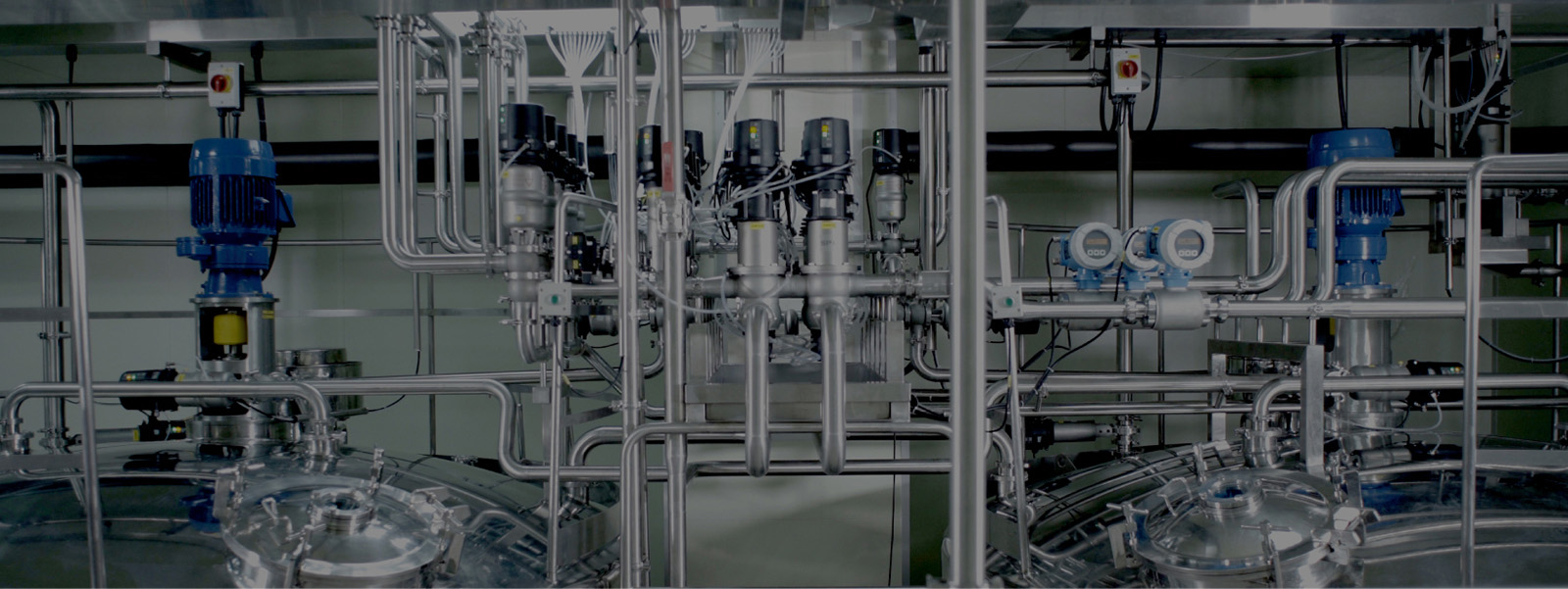

Our Liquid Process System is capable to produce the tea and fruit juice (fibers or cubes) products. It have several formula settings to fulfill different inquiries. Meanwhile, there are monitoring devices such as flow meter, conductivity meter and so on, to collect different information in the production line then integrate the information to provide the report.

The pasteurize system is used for pasteurizing the dairy and many different kind of beverages; such as dairy drinks, concentrate tea liquid, juice, sugar syrup and water product (include the beverage with particle or fibers). The main purpose for this equipment is to extend the shelf life of product.

Target possesses the best hot filling bottle lightening technology in the world. Certificated with both HACCP and FSSC22000, we are able to design various bottles from 250ml to 2000ml and both 28mm and 38mm mouthed bottles.

Capping machine using sterile water to clean closures, it without contamination, chemical or residual plastic particle. The closure size suitable for 28mm and 38mm.

Rinser / Filler / Capper in one filling system, it fulfill HEPA10000 criteria, to ensure the hygienic cleanliness without problem. Independence CIP system, various bottle size at filler with unique technology under stable capacities.

With 40 seconds sterilization of filled bottles.

The tunnel cooler is designed to meet different conditions, to appointed the temperatures by recycle with heat, warm, and cooling water to spraying system. It can be controlled by automation setup at temperature and timing.

Dual-head machine design, it can operate by single or dual-head mode, to save more spaces and effectively applicable to non-stop production line with output pressure. And it equipped with specific PLC control system.

The machine is suitable for carton and shrink-film package, by use of Wrapping around and tray packing and several optional accessories can be chosen. Take use of PLC control, provided with human-machine interface for easy operation.

The machine is suitable for carton, shrink-film, tray, drum, etc. to meet with various packaging types. Take use of PLC control, provided with human-machine interface easy to operation.